Description

|

MAIN PRODUCTION LINE |

||||

| Model | Pipe Diameter(mm) | Extrusion speed(Kg/H) | Power(KW) | Floor Area(m*m) |

| WSP3000-75 | DN200-DN3000 | 400-620 | 300 | 40*18 |

| WSP3000-75+45 | DN200-DN3000 | 400-620 | 345 | 40*18 |

| WSP4000-90 | DN200-DN4000 | 500-900 | 382 | 40*18 |

| WSP4500-90+45 | DN200-DN4500 | 500-1000 | 427 | 40*18 |

| Note: The type of extruder configuration with the Arabic numeral 45 can produce pipes with a special color inner wall. | ||||

|

PP SINGLE-WALL CORRUGATED PIPE UNIT |

||||

| Model | Pipe Diameter(mm) | Extrusion speed(Kg/H) | Power(KW) | Floor Area(m*m) |

| CSP120-65 | φ21-130 | 150 | 85 | 18*3.5 |

| CSP120-75 | φ21-130 | 200 | 105 | 18*3.5 |

|

WINDING MOLD |

||||

| DN200 | DN300 | DN400 | DN500 | DN600 |

| DN700 | DN800 | DN1000 | DN1200 | DN1400 |

| DN1500 | DN1600 | DN1800 | DN2000 | DN2200 |

| DN2400 | DN2500 | DN2600 | DN2800 | DN3000 |

FULL DIAMETER SERIES WINDING MANDREL

Mandrel features:

- Small sizes mandrel with high lengthdiameter ratio, no bendling or deformation.

- High strength design of large diameter mandrel, resistance to the shrinkage pressure of thick wall pipe material, good coaxiality, high roundness.

- Large diameter mandrel with patent design, drived by power, high strength, stable and accurate safe operation.

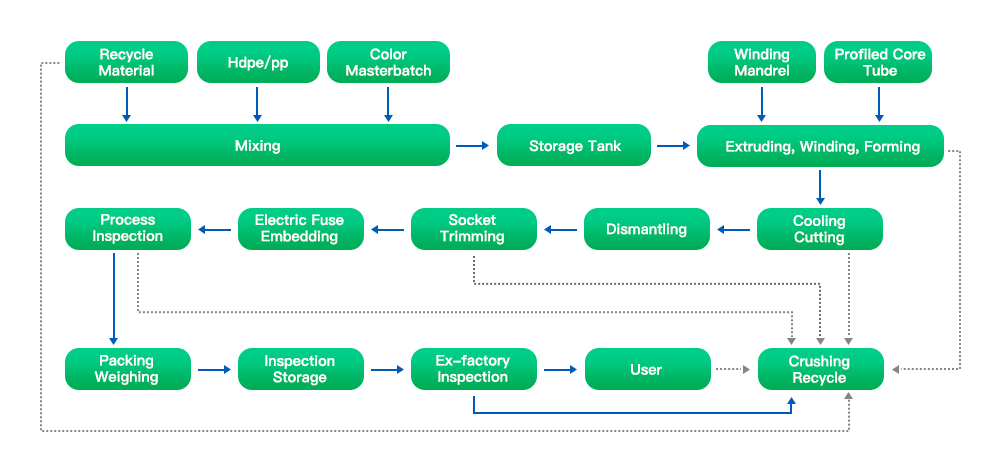

PRODUCTION TECHNOLOGY AND PROCESS

The product is made of high-density polyethylene/polypropylene resin mainly and polypropylene single wall corrugated pipe as the auxiliary support.The production and processing adopt the hot extrusion and spiral winding forming process.

The flat belt extruded by the extruder and PP corrugated pipe coating by the "O"type wrapped support,are evenly wound on the heated steel mandrel according to the predetermined position, making the structural wall pipe body with high resistance to external pressure.Then followed by natural wind cooling,cutting,dismantling,trimming,embedded electro fusion welding wire,inspection and other subsequent processes the final pipe products are manufactured out.